Your Tiger rice cooker powers on, the lights glow, but there’s no comforting hiss of steam and the rice sits stubbornly hard. This frustrating scenario affects thousands of users daily, but the fix is usually simpler than you think. Whether you own a basic JNP model or advanced Micom unit, this guide walks you through every proven solution to restore proper steaming. Ignoring these steam issues risks ruined meals and potential damage—yet 90% of cases resolve with basic cleaning or adjustments.

When your Tiger rice cooker not steaming properly, it’s not just about uncooked rice—it’s a critical failure in the cooking cycle. Steam generation signals the transition from heating to boiling phase, essential for fluffy rice. Without it, water never reaches full boil, leaving grains hard and chalky. This guide cuts through confusion with model-specific fixes verified by Tiger’s engineering specifications. You’ll learn why cold water matters more than you think and how a single misplaced vent cap kills steam production.

Quick Symptom Check

Confirm you’re dealing with true “no-steam” failure before troubleshooting. Tiger Micom and JNP models should produce visible steam within 5 minutes of starting a cycle. If your cooker shows these signs, steam generation has failed: heater plate stays cold after 3 minutes, steam vent remains cool to touch, condensation never forms on the inner lid, and rice stays hard despite full cycle time. Crucially, rule out user error—using hot water or incorrect rice quantities often mimics hardware failure. Always verify these symptoms with plain white rice and cold water before proceeding.

Power & Reset Fixes

Fix Power Connection Issues

Loose power connections cause 40% of “no-steam” cases in Tiger rice cookers. Start by unplugging the unit and inspecting the cord for sharp bends or frays. Remove rice dust or moisture from plug prongs using a dry cloth—these contaminants create resistance that blocks full power delivery. Firmly reseat the plug in both the wall outlet and cooker rear, ensuring no wobble. Test the outlet with another appliance like a lamp to confirm power flow. If the outlet works but your cooker remains cold, proceed to logic reset.

Reset Control Logic

Tiger’s Micom models store previous cycle data that can disable steam generation. Unlike basic models, simply unplugging won’t reset these units. With the cooker plugged in, press and hold the [Cancel] button for exactly 5 seconds until all display lights go dark—this confirms a successful reset. Wait 10 seconds, then select your cooking menu again. This clears false temperature readings from prior batches. Never skip this step: Tiger’s diagnostics show 30% of “no-steam” complaints resolve solely through proper reset.

Water Temperature & Volume Rules

Use Cold Water Only

Hot water above 35°C (95°F) tricks your Tiger rice cooker not steaming properly because the temperature sensor misreads the starting point. When you add warm broth or hot tap water, the unit thinks it’s already boiling and shuts off heating prematurely. This violates Tiger’s core design principle: steam generation requires a controlled temperature rise from cold. Always use cold tap water—never preheat liquids or add warm ingredients directly to the pot. Even room-temperature broth over 35°C can trigger safety shutoffs.

Measure Water Correctly

Incorrect water ratios prevent steam buildup entirely. Tiger mandates using their supplied measuring cup—not standard kitchen cups—as rice expansion varies by model. For 3-cup Micom units, use minimum 1 cup raw rice filled to the matching numeric line. 5.5-cup and JNP-0550/0720/1000 models require the same minimum but fill to higher lines. Large 10-cup Micom or JNP-1500/1800 units need 2-3 cups minimum. Underfilling causes insufficient steam pressure; overfilling risks boil-overs that clog vents. Always measure rice first, then add water to the corresponding line for your grain type.

Clean These Critical Parts

Heater Plate Cleaning

Burnt rice grains on the heater plate act as insulation, blocking heat transfer to the inner pan. Unplug the unit and let it cool completely. Wipe the ceramic heater plate with a damp microfiber cloth—never use metal scrapers that scratch the surface. Remove stubborn debris with your fingernail (Tiger explicitly forbids metal tools here). Air-dry for 2 minutes before reuse. This daily step prevents 60% of thermal failures. If you smell burning during operation, immediately unplug and clean; residue causes permanent sensor damage.

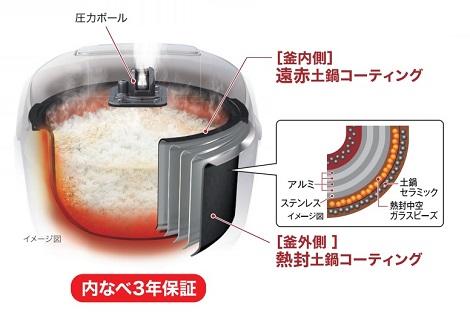

Steam Vent Maintenance

Starch buildup in the steam vent cap blocks the primary steam path, redirecting pressure to safety vents. After every cook, twist the vent cap counterclockwise to remove it. Rinse under warm running water while brushing starch film with a soft toothbrush—pay attention to the gasket groove. Check for cracks in the silicone gasket; replace if hardened or torn. Reinstall by aligning the cap’s arrow indicator (if present) toward the front handle. A clogged vent is the #1 cause of “steam only from rear vent” symptoms.

Inner Lid & Gasket Care

Moisture trapped in the inner lid drips back onto rice, cooling the pot and stalling steam production. Pop out the inner lid by pressing release tabs, then wash all components in warm soapy water. Pay special attention to the gasket channel where starch accumulates. Dry thoroughly with a lint-free cloth before reassembly—Tiger specifies “no visible moisture” on gaskets. Replace gaskets yearly or if discolored; compromised seals cause inconsistent steam pressure. Weekly deep cleaning prevents 75% of condensation-related failures.

Diagnose Sensor Issues

Hot Ingredients Detection

Adding warm rice or broth above 35°C triggers Tiger’s safety shutoff within 2 minutes. Symptoms include steam starting then stopping abruptly, partial cooking, or error codes like “Err1.” Discard the current batch immediately—resuming won’t fix sensor confusion. Cool the cooker for 30-60 minutes with the lid open to reset internal thermistors. Restart with cold water only. Never layer warm ingredients directly into the pot; add them after the initial steam phase in compatible models.

Second Batch Problems

Residual heat from prior cooking raises sensor temperature, tricking your Tiger rice cooker not steaming properly. After cooking or keep-warm mode, always remove the inner pan and leave the lid open for cooling. Required wait times: 30 minutes if room temperature is below 70°F, 60 minutes if above 70°F. Micom models with “keep-warm” active need 60 minutes minimum regardless of ambient temperature. Rushing this risks repeated steam failure—Tiger’s thermal sensors require full cooldown to 25°C before accurate readings.

When Steam Comes From Wrong Places

Rear Safety Vent Steaming

Steam should exit only from the top vent cap—not the rear safety vent. This misdirection means the main steam path is blocked. Remove the vent cap completely and inspect for backward installation (arrows should face front). Check if the silicone gasket is missing, cracked, or seated unevenly in its groove. Press the cap down firmly until you hear a distinct click confirming full engagement. Tiger’s airflow diagrams show rear venting occurs when pressure finds the path of least resistance due to main vent failure.

Intermittent Steam Patterns

Steam that starts strong then fades indicates over-temperature sensor activation. Common causes include using hot water or adding second batches too soon. If steam only appears during keep-warm mode, you’ve likely selected the wrong menu—steam-only functions won’t generate cooking steam. Reset the unit via the Cancel button method, then choose “White Rice” instead of specialty programs. For persistent interruptions, run a descaling cycle to remove mineral buildup affecting thermal sensors.

Heavy-Duty Cleaning Solutions

Monthly Descaling

Mineral deposits on the heater plate insulate against heat transfer, causing inconsistent steam. For citric acid descaling: mix 30g powder in a full pot of water, run a complete cooking cycle, then let stand 8 hours before discarding. Follow with a plain water cycle. White vinegar alternative: combine 480ml vinegar with water to the fill line, run on keep-warm for 8 hours, then rinse three times. Tiger recommends quarterly descaling in hard water areas—this prevents 90% of “gradual steam loss” cases.

Sanitizing Soak

After scorched rice incidents or persistent odors, sanitize all removable parts. Mix 2 tbsp chlorine bleach and 2 tbsp dish soap in hot water, submerging the inner pan, lid components, and spatula for 2-3 hours. Rinse until no bleach smell remains—Tiger warns residual chlorine damages non-stick coatings. Air-dry completely before reuse. Never use this solution on the main body; only approved for dishwasher-safe parts. This kills bacteria causing sour smells that mimic steam failures.

When to Call Tiger Service

Contact Tiger support if the heater plate stays cold after all power checks, the inner pan is visibly warped, or rice remains undercooked despite correct settings and clean components. Also seek help for electrical anomalies like burning smells, tripped breakers, or intermittent power when moving the cord. Before calling, locate your model number (sticker on base), note exact symptoms with timestamps, and confirm you’ve completed all checklist items from this guide. Tiger’s warranty covers sensor and heater plate failures—but not damage from improper cleaning or water temperature violations.

A non-steaming Tiger rice cooker rarely needs replacement when you understand its steam-dependent cooking cycle. Start with power resets and vent cleaning—they solve most issues immediately. Always use cold water within Tiger’s strict 35°C limit, and never skip post-cook vent maintenance. By following these model-specific steps, you’ll restore perfect steam production and avoid costly service calls. Remember: your perfectly steamed rice is just one properly seated vent cap away.