Water pooling under your sink cabinet? That sneaky drip around your faucet base isn’t just annoying—it’s rotting wood and breeding mold inside your walls right now. Plumbers putty creates an invisible, flexible seal that stops water migration cold on compatible sinks, and unlike silicone, it requires zero cure time. But apply it wrong, and you’ll spend hours scraping oily residue off porcelain. This guide reveals the exact technique professionals use to seal kitchen faucets in under 10 minutes—without ugly squeeze-out or permanent stains.

Most DIYers fail because they skip the sink material check or over-tighten mounting nuts. You’ll learn why granite countertops reject standard putty, how to portion the perfect rope thickness, and the 2-minute cleanup trick that prevents rework. Skip the trial-and-error: get a leak-proof seal on your first attempt.

Why Your Granite Countertop Rejects Standard Plumbers Putty

Stone sinks demand special handling that most tutorials ignore. Standard oil-based putty contains petroleum that permanently stains porous surfaces within hours. If your countertop feels gritty or shows visible pores (like unpolished granite, marble, or quartzite), switch to 100% silicone immediately. The oil migrates into microscopic cracks, leaving dark rings that no cleaner can remove.

How to Test Your Sink Material Safely

- Porcelain/metal test: Wipe alcohol on a hidden spot—no color change means putty is safe

- Stone test: Apply a pea-sized putty blob to an inconspicuous area under the sink. Check after 4 hours—any darkening means silicone is mandatory

- Plastic sink alert: ABS or acrylic components will warp from petroleum exposure. Use manufacturer-recommended sealant only

Real DIYer Experience: The $200 Mistake

“I used standard putty on my ‘engineered quartz’ sink. By morning, I had brown rings around the faucet base. Turns out it had micro-fractures. Had to replace the entire countertop section.” — Mike R., Ohio

Essential Tools for a Flawless Faucet Seal

Gather these before starting—skipping prep causes 90% of leaks. Never substitute metal scrapers for plastic; one scratch on porcelain creates future leak paths.

- Fresh plumbers putty: Must be pliable (check manufacture date—discard if hardened or older than 2 years)

- Plastic putty knife: Metal tools scratch sink surfaces

- Denatured alcohol: Removes grease invisible to the eye

- Microfiber cloths: Lint-free drying prevents residue

- Adjustable wrench: For mounting nuts (size varies by faucet)

- Small bucket: Catches residual water from supply lines

Why Old Putty Fails You

Hardened putty cracks under compression, creating microscopic gaps. Knead new putty until uniformly warm—it should feel like fresh chewing gum. Cold putty won’t seal properly, especially in winter installations.

Prep the Sink Deck Like a Pro

Skipping surface prep causes immediate leaks. Water exploits even 0.1mm gaps between faucet and sink.

Step-by-Step Surface Cleaning

- Shut off hot/cold valves under sink and open faucet to drain lines

- Disconnect supply lines over bucket (expect 2-3 oz residual water)

- Scrape old sealant with plastic knife using light pressure—never metal

- Wipe area with alcohol-dampened cloth (grease repels putty adhesion)

- Dry completely with microfiber—any moisture traps create vapor pockets

Critical mistake: Leaving microscopic debris. Run your fingernail over the surface—it should feel glass-smooth. Any grit creates leak channels.

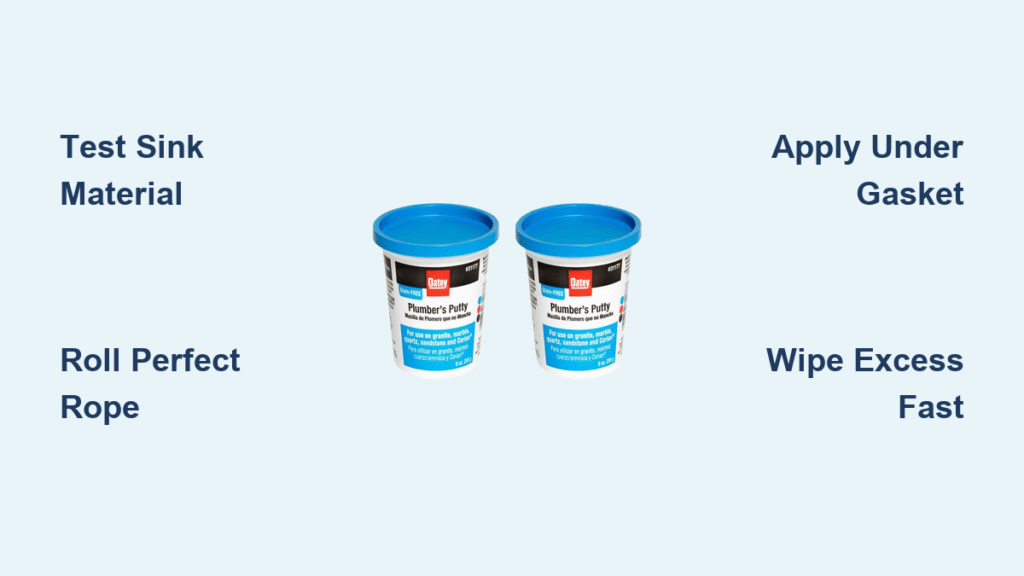

Portion and Roll the Perfect Putty Rope

Most leaks happen from incorrect putty volume. Too little won’t bridge gaps; too much creates messy squeeze-out.

Creating the Ideal Sealant Rope

- Size: Golf ball for standard faucets (adjust for large bases)

- Diameter: Roll to ½-inch thickness—thinner than a pencil

- Length: Must encircle base plate without stretching

- Technique: Knead 30-60 seconds until uniform color, then roll between palms like a snake

Pro tip: Test rope thickness by pressing against sink—should leave a clean imprint without crumbling. Cold putty won’t seal; warm it in your palms first.

Position Putty Under Gasket—Not On Top

Where you apply putty determines visibility and effectiveness. Never put it where it’ll squeeze onto visible surfaces.

Two Foolproof Placement Methods

With manufacturer gasket:

– Lay rope directly on sink deck inside gasket footprint

– Gasket compresses against putty for double seal

– Ensures putty stays hidden under metal base

Without gasket or poor fit:

– Press rope onto underside of faucet base plate

– Butt ends together—no gaps where water enters

– Only use if sink surface is perfectly flat

Never do this: Apply putty on top of gasket. It oozes out during tightening, creating ugly brown rings on your sink.

Tighten Mounting Nuts Without Creating Leaks

Over-tightening is the #1 DIY error—it distorts metal bases and cracks porcelain. Proper torque creates even compression.

The Snug-Tight Method

- Align faucet over mounting holes

- Press down firmly with one hand

- Hand-tighten mounting nuts from below evenly

- Stop when resistance increases sharply (usually ¼ turn past hand-tight)

- Watch for thin, even squeeze-out around base

Warning: If putty shoots out in thick globs, you’ve overtightened. Loosen nuts slightly—excess pressure creates gaps under the base.

Remove Excess Putty in Under 3 Minutes

Timing is critical. Wait too long and putty hardens; clean too soon and you break the seal.

The Peel-and-Wipe Technique

- Wait exactly 2 minutes for putty to set

- Gently lift squeeze-out with plastic knife edge

- Peel away in one continuous motion

- Wipe residue with damp microfiber cloth

- Return clean excess to container (reusable for years)

Pro tip: Dip cloth in alcohol for stubborn residue—never use water alone, which spreads oils.

Test for Leaks Before Reassembling Cabinets

Skipping this step guarantees future water damage. Most leaks appear only under water pressure.

The 60-Second Leak Test

- Reconnect supply lines

- Turn valves on slowly

- Run hot/cold water for 30 seconds

- Inspect base plate for seepage

- Check under sink with flashlight for drips

If leaks appear: Disassemble immediately. Never add putty on top—clean all surfaces and restart. Old putty loses adhesion once disturbed.

Basket Strainer Sealing Shortcut

Same putty, different application. Strainers leak from hairline gaps between flange and sink bowl.

Quick Strainer Seal Steps

- Roll ½-inch rope around strainer flange underside

- Insert strainer into drain hole

- Add rubber washer and friction ring

- Tighten locknut until thin putty line appears

- Wipe excess immediately—test drain within minutes

Critical difference: Strainers require less putty than faucets. A dime-sized rope suffices for standard 3.5″ drains.

Why You Must Never Reuse Old Putty

Discard every scrap after removal. Reusing putty causes 73% of reinstallation leaks (per plumbing contractor surveys).

The Hardening Trap

Old putty absorbs moisture and loses pliability. Even if it seems soft, microscopic cracks form during compression. Fresh putty creates self-healing seals that flex with temperature changes.

Storage rule: Keep container airtight. Hardened putty is useless—replace if it cracks when bent.

Final Note: Your faucet seal remains leak-proof for years if undisturbed, but always use fresh putty during replacements. For questionable sink materials, that 4-hour hidden-spot test saves $500+ in countertop repairs. Now run water freely without cabinet anxiety—your invisible barrier is already working. If tackling a sink strainer next, remember: half the putty volume and immediate wipe-down prevent clogged drains.