You’re mid-summer cookout, flipping burgers while guests sip drinks at your outdoor kitchen—then you need to rinse veggies. Suddenly, you’re trudging inside, tracking dirt through your house while the party cools down. An outdoor sink isn’t just convenient; it’s the backbone of seamless outdoor entertaining. But skip proper plumbing, and that dream setup becomes a frozen pipe nightmare come winter. This guide reveals exactly how to plumb outdoor kitchen sink systems that handle daily use and survive subzero temperatures—using DIY-friendly methods that save thousands over professional installs. You’ll learn precise trench depths, material hacks that prevent burst pipes, and drainage tricks that keep your yard dry even after heavy rain.

Most homeowners overcomplicate outdoor plumbing by chasing hot water lines or sewer connections. Cold water-only systems cut costs by 70% while handling 95% of outdoor tasks. The secret? Strategic pipe routing that leverages gravity for foolproof winterization. In the next 15 minutes, you’ll master pipe materials that won’t crack in freezing temps, dry wells that drain instantly in clay soil, and a 5-minute blow-out method that prevents $500 emergency repairs. Let’s transform your outdoor kitchen from a summer-only accessory to a year-round asset.

Select Your Cold Water-Only Sink Configuration

Skip Hot Water Lines for Cost Efficiency

Cold water-only setups dominate successful outdoor kitchens—eliminating complex hot water runs, insulation headaches, and $300+ tankless heaters. You’ll save $800–$1,500 on installation while avoiding freeze risks from intermittent hot water use. If warm water is essential, install a point-of-use tankless heater directly under the sink cabinet. These compact units ($150–$250) heat on demand without long pipe runs from your house. Never attempt to extend existing hot water lines outdoors; temperature swings cause premature joint failures.

Choose Freeze-Resistant Sink and Faucet Materials

304-grade stainless steel sinks withstand sun exposure and temperature extremes without warping or rusting. Avoid cheaper 201-grade stainless—it corrodes within 18 months when exposed to outdoor elements. For faucets, demand solid brass construction with PVD finish. This vapor-deposited coating won’t peel like painted finishes when bombarded by UV rays. Crucially, inspect for plastic internal components; they become brittle within one winter season. Test faucet handles outdoors for 30 days before installation—any stiffness indicates poor cold-weather performance.

Route Water Supply Lines for Foolproof Winterization

Tee Off Existing House Plumbing Correctly

Locate the nearest interior cold water line—typically under an adjacent bathroom sink or kitchen cabinet. Measure the distance to your outdoor sink location, then calculate a route through conditioned spaces first (like basements or closets) before exiting through the rim joist. Maintain a consistent 1/4-inch-per-foot slope back toward your house on the outdoor run. This subtle angle allows gravity to drain 95% of water during winterization. Never slope toward the sink—this traps water in low spots that inevitably freeze.

Install Freeze-Tolerant PEX-A Tubing

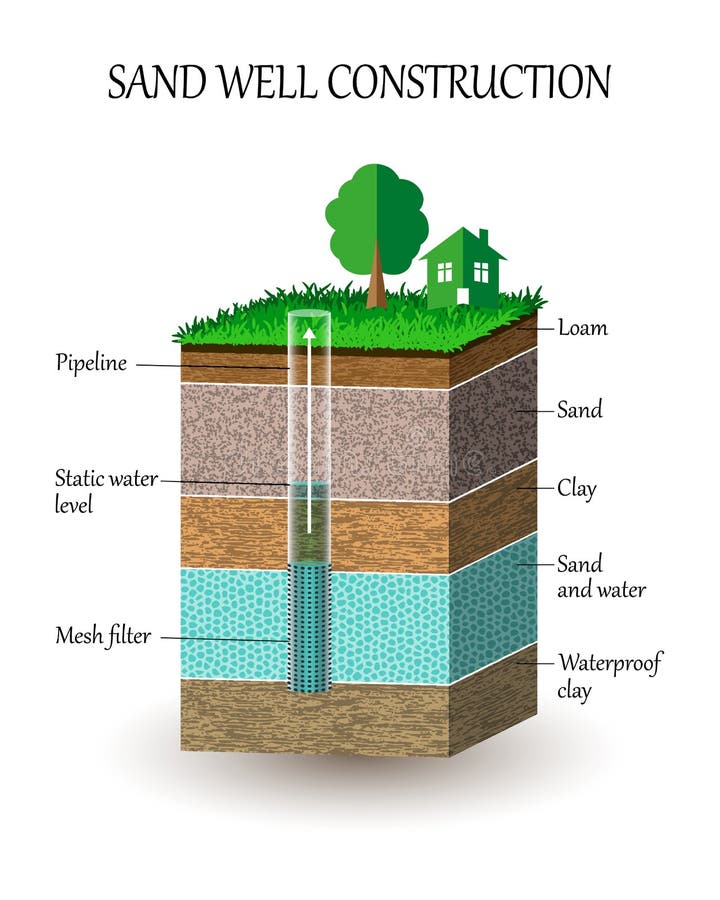

PEX-A tubing (1/2-inch diameter) outperforms all alternatives for outdoor runs. Its cross-linked polyethylene structure expands 300% when frozen without rupturing—unlike rigid PVC or copper. Rent a $15 cinch clamp tool for weekend installation; avoid crimp rings which fail under soil pressure shifts. Bury lines 6 inches below local frost depth (typically 36–42 inches). For wall penetrations, drill a 1-inch hole through the rim joist using a hammer drill, then sleeve the pipe in PVC conduit sealed with 100% silicone caulk on both sides. This prevents moisture intrusion while allowing thermal expansion.

Install Critical Winterization Valves Before Burial

Position Interior Shut-Off with Outdoor Drain Access

Install a full-port ball valve inside your home immediately after the tee connection to the main line. This valve must be easily accessible year-round—never bury it behind insulation. On the outdoor side of this valve, add a boiler drain (hose bib). This $8 component creates a gravity drainage point for winterizing: open the outdoor faucet and boiler drain simultaneously to evacuate 90% of water without air compressors. Label the interior shut-off valve with bright tape—searching for it in freezing temps causes costly delays.

Execute the Two-Step Blow-Out Method

Before first freeze, close the interior ball valve, then open both the outdoor faucet and boiler drain for 10 minutes. Next, connect a regulated air compressor (set to 30–50 PSI) to the boiler drain via quick-connect fitting. Blow air through the line for 30 seconds until it runs clear. Finally, pour 1 cup of RV antifreeze into the P-trap to protect against residual moisture. This process takes 5 minutes and prevents 99% of freeze damage—no expensive heat tape required.

Build Drainage That Handles Heavy Soil Conditions

Construct a Clay-Soil Dry Well That Drains Instantly

In slow-draining clay soils, standard dry wells fail within months. Instead, dig a 4-foot-deep hole 12 feet from your foundation (minimum). Line it with landscape fabric, then add 14 inches of #57 gravel. Place a 55-gallon perforated drum (drill 1/2-inch holes on 4-inch grid) on the gravel base. Connect your 1.5-inch PVC drain pipe to an inlet hole in the drum’s upper third. Fill around the drum with gravel, wrap the top with fabric, and backfill soil slightly mounded. This layered design creates a 400-gallon absorption capacity—enough to handle a full sink dump in heavy clay.

Install French Drain With Downward-Facing Perforations

For high-volume use (like commercial outdoor kitchens), use a French drain with 4-inch perforated pipe. Dig an 18-inch-deep trench sloping 1 inch per 8 feet away from your sink. Lay pipe with perforations facing downward to prevent clogging, then surround it with gravel wrapped in landscape fabric. Connect the sink’s P-trap to the French drain via a 1.5-inch-to-4-inch reducer. The downward holes allow water to seep into surrounding soil while preventing silt from entering the pipe—critical for longevity in clay conditions.

Complete Your Plumbing in 8 Critical Steps

Call 811 and Verify Frost Depth First

Before digging, call 811 for utility locates—hitting a gas line risks explosion. Confirm your local frost depth via municipal codes; in Minnesota it’s 48 inches, while Georgia requires only 12 inches. Dig supply and drain trenches simultaneously to minimize yard disruption. For supply lines, bury PEX 6 inches deeper than frost depth; for drains, maintain 1/4-inch-per-foot slope using a 4-foot level and string line.

Pressure-Test Lines Before Backfilling

After connecting all joints, pressurize supply lines to 60 PSI for 30 minutes using a $15 test gauge. Check every connection with soapy water—bubbles indicate leaks needing immediate repair. For drains, fill the sink completely and time drainage; water should clear within 60 seconds. If sluggish, increase slope by 1/8 inch per foot. Backfill trenches in 6-inch layers, tamping soil to prevent future settling.

Prevent Costly Winter Damage With Annual Routine

Winterize Before First Frost Warning

Mark your calendar for October 15 (adjust for your climate zone). Close the interior ball valve, open outdoor faucet and boiler drain for 10 minutes, then blow out lines with compressed air. Pour RV antifreeze into the P-trap—never automotive antifreeze, which damages pipes. In spring, reverse the process: close outdoor valves, slowly open interior valve, and run water for 2 minutes to flush sediment.

Essential Tools and Budget-Saving Supplies

Rent Smart to Cut DIY Costs

For a 30-foot run, spend $150–$200 on materials:

– PEX-A tubing ($0.50/ft) and stainless cinch clamps ($0.75/clamp)

– 1.5-inch Schedule 40 PVC for drains ($2.50/ft)

– Landscape fabric and #57 gravel ($80 for dry well)

Rent a PEX crimp tool ($15/day) and trencher ($75/day) instead of buying. Skip hot water lines and sewer connections to avoid $1,300–$3,500 professional fees.

Fix Slow Drains and Freeze Damage Immediately

Diagnose Drainage Failures in 5 Minutes

Symptom: Water pools around sink after use.

Cause: Saturated dry well from clay soil or inadequate gravel.

Fix: Pump water from the well, add 12 inches of fresh gravel, and rewrap with landscape fabric. If recurring, relocate the dry well 20 feet downhill.

Symptom: Faucet sputters after winter restart.

Cause: Air trapped in high points of the line.

Fix: Open the highest faucet in the system (often an indoor bathroom) to bleed air while running water.

Maintain Peak Performance With 10-Minute Weekly Tasks

Flush supply and drain lines with hot water weekly to prevent grease buildup. Clean the sink strainer after every use—food particles cause 80% of clogs. In spring, inspect your air admittance valve (AAV) for free movement; stuck valves cause slow drainage and sewer odors. Every 5 years, pump sludge from dry wells using a wet-dry vacuum—this extends system life by 10+ years.

Your outdoor kitchen becomes truly functional when plumbing works flawlessly from July heat to January freezes. By implementing these precise techniques—PEX-A tubing sloped toward the house, boiler drain valves for effortless winterization, and clay-soil dry wells with downward-perforated drums—you’ll avoid the #1 reason outdoor sinks get abandoned: winter damage. Start this weekend by calling 811 and sketching your route. In one day, you’ll install a system that handles summer BBQs and survives -20°F nights, all for under $200. The next time it’s raining during dinner prep, you won’t be running indoors—you’ll be rinsing herbs right where the party happens.