When your dinner rush hits and tickets are piling up, knowing how to manage a restaurant kitchen separates thriving establishments from those barely surviving. Most operators waste 30-40% of potential profits through disorganized back-of-house operations. This isn’t about fancy cooking techniques—it’s implementing proven systems that transform chaos into controlled efficiency. You’ll discover specific, actionable strategies to reduce food waste, optimize labor costs, and build a kitchen team that performs consistently under pressure, all while maintaining food quality your customers expect.

The difference between a kitchen that barely breaks even and one that generates real profit lies in systematic management. Without clear protocols, even talented chefs watch margins evaporate through preventable waste and staff turnover. This guide delivers specific, field-tested approaches—not theoretical concepts—to give you immediate control over your kitchen operations starting today.

Kitchen Manager vs. Chef Role Distinction That Prevents Costly Overlaps

Stop mixing administrative and culinary responsibilities that drain your profitability. Your kitchen manager must handle purchasing, inventory control, scheduling, and cost management while your chef focuses solely on menu development and food quality. When owners try to wear both hats without clear boundaries, critical tasks fall through the cracks—like forgetting to adjust menu prices when avocado costs jump 40%.

Daily Role Separation Techniques

Implement these simple but critical distinctions:

- Morning meeting structure: Kitchen manager reviews inventory reports and labor costs first, then chef presents new menu items

- Decision authority mapping: Clearly define who approves vendor changes, recipe modifications, and staff scheduling

- Financial dashboards: Kitchen manager tracks food/labor costs while chef monitors food quality metrics

Critical mistake to avoid: Letting your chef approve vendor substitutions without cost analysis. That “better quality” olive oil might destroy your profit margin on pasta dishes.

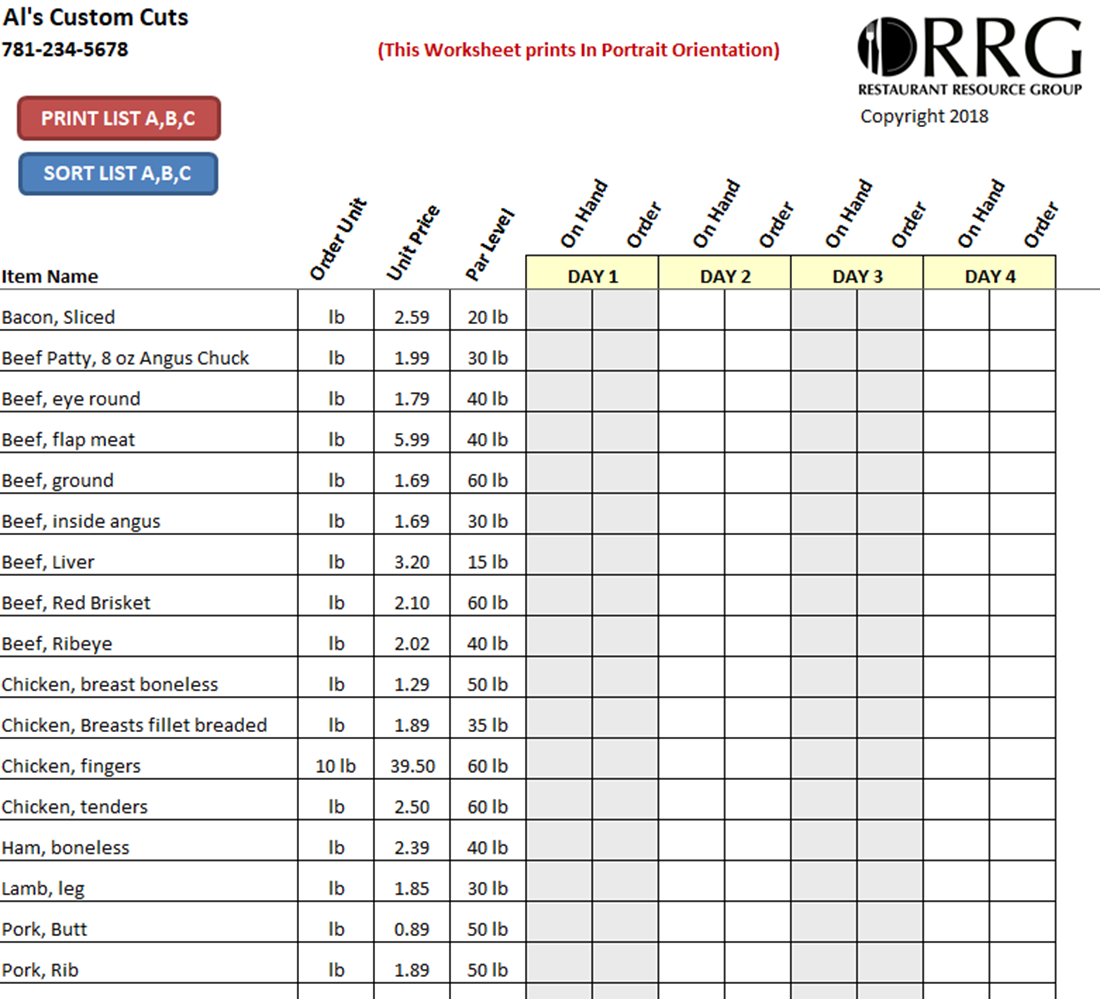

Order Guide System That Eliminates Emergency Supplier Runs

Create supplier-specific reorder documents that prevent both shortages and overstocking. Generic “order more tomatoes” instructions cause 68% of inventory issues according to restaurant efficiency studies. Your order guide must include supplier contacts, minimum order quantities, par levels based on 7-day sales averages, and seasonal demand adjustments.

Implementing Your Order Guide in 3 Steps

- Build your living document: List each ingredient with supplier name, contact, minimum order amount, and current par level

- Set smart reorder points: Calculate using formula: (Daily usage × Lead time) + 10% buffer

- Track seasonal adjustments: Increase tomato orders by 25% during summer salad season but reduce by 40% in winter

Pro tip: Set digital alerts at 90% of your reorder point. This buffer prevents panic orders when suppliers face unexpected delays.

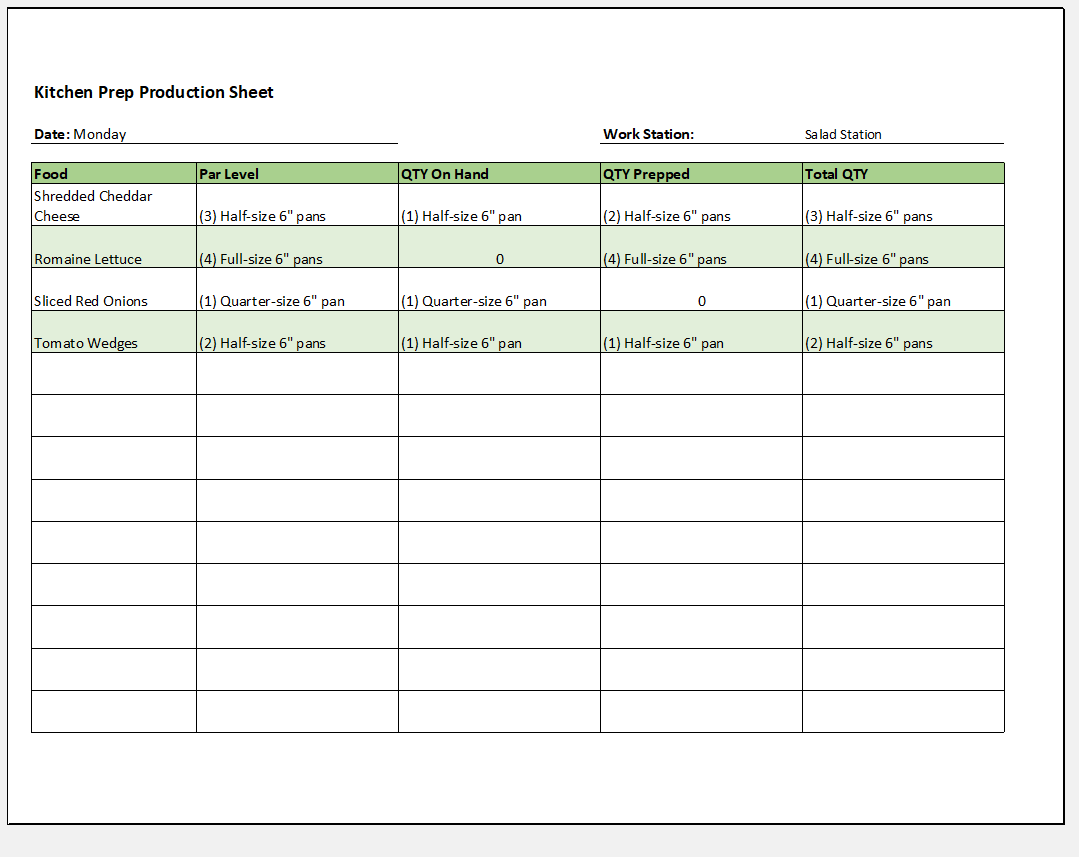

Prep List System That Guarantees Consistent Ingredient Availability

Transform vague “prep vegetables” instructions into specific, measurable tasks that ensure kitchen readiness. Generic prep lists cause inconsistent portioning and last-minute scrambling during service. Your prep list must specify exact quantities, preparation methods, and completion times for each station.

Creating Station-Specific Prep Lists

Grill station example:

– Monday: Portion 15 lbs ribeye (8 oz each), trim 10 lbs asparagus

– Tuesday: Marinate 20 lbs chicken thighs, dice 12 lbs onions

– Wednesday: Prepare 15 lbs burger patties, julienne 8 lbs bell peppers

Post these at each station with completion deadlines. Your morning crew knows precisely what’s required before service begins, eliminating “I thought someone else did that” excuses.

Work Station Checklists That Prevent Service Disasters

Implement station-specific verification protocols that catch issues before customers notice. No more discovering you’re out of burger buns at 7 PM on a Friday night. Each station needs tailored pre-service checks with supervisor sign-off.

Essential Grill Station Checklist

- Verify protein portions (8 oz steaks, 6 oz chicken breasts)

- Confirm oil temperature (350°F for frying)

- Check grill heat zones (high/medium/low)

- Prepare garnishes (chopped parsley, lemon wedges)

- Confirm backup protein availability

Critical step: Require supervisor initials after each station completes checks. This accountability prevents skipped steps during rushed preps.

Data-Driven Staff Scheduling That Optimizes Labor Costs

Build schedules using actual sales data, not gut feelings. Restaurants that schedule based on historical patterns reduce labor costs by 12-18% without sacrificing service quality. Your schedule must account for weather patterns, local events, reservation counts, and historical sales data.

Creating Your Scheduling Formula

- Weather factor: Increase prep staff 20% for rainy Saturdays (delivery orders spike 35%)

- Event calendar: Add 2 line cooks during local theater performances

- Reservation tracking: Schedule extra staff when bookings exceed 75% capacity

- Historical analysis: Compare this week to same period last year for accuracy

Pro tip: Document each employee’s skill matrix (Sarah: Grill expert, Salad competent) to build flexible schedules when staff call in sick.

Food Cost Control System That Protects Your Margins

Track ingredients to the penny with a system that calculates exact dish costs including waste. Restaurants with precise food costing maintain 5-8% higher profit margins than those guessing at costs. Your system must include recipe costing, market monitoring, and waste tracking.

Implementing Daily Food Cost Controls

- Calculate exact recipe costs: Include every gram of ingredient plus waste factor

- Monitor market prices daily: Adjust menu prices immediately when key ingredient costs change

- Track waste patterns: Log discarded items to identify prep or portioning issues

Quick formula: If your target food cost is 30% and a dish costs $4.50 to make, minimum menu price = $15.00. Any lower and you’re losing money.

Digital Safety Logs That Pass Health Inspections Easily

Replace paper temperature logs with digital systems that send real-time alerts to your phone. Restaurants using digital safety logs pass health inspections 27% more often according to industry data. Your system must track temperatures, expiration dates, and generate compliance reports instantly.

Essential Daily Safety Routine

- 10 AM: Check walk-in temperatures (below 40°F for refrigeration)

- 2 PM: Verify freezer temps (0°F or lower)

- 6 PM: Confirm hot holding temperatures (above 140°F)

- Document everything: Health inspectors favor detailed, timestamped records

Critical step: Train staff to log temperatures immediately after checking—never from memory later.

Menu Engineering Strategy That Boosts Profitability 15%

Categorize dishes using POS data to identify hidden profit killers. Restaurants that analyze menu performance increase profits by optimizing their offerings rather than guessing. Your analysis must classify dishes as Stars (high profit, high popularity), Puzzles (high profit, low popularity), Plowhorses (low profit, high popularity), and Dogs (low profit, low popularity).

Actionable Menu Optimization Steps

- Stars: Feature prominently (e.g., prime menu placement, server recommendations)

- Puzzles: Rename or reposition on menu to increase visibility

- Plowhorses: Slightly increase price or reduce portion size

- Dogs: Remove or completely revamp with cross-utilized ingredients

Pro tip: Design menus that use ingredients across multiple dishes (cilantro in tacos, salsa, and soup garnish) to reduce waste by up to 22%.

Kitchen Display System That Reduces Order Errors 35%

Replace paper tickets with digital screens that color-code order times and prioritize by promised service. Restaurants using KDS systems reduce order errors by 35% and improve ticket times by 18%. Your system must visually highlight urgent orders and track individual station performance.

Implementing Effective KDS Protocols

- Color coding: Green = on time, yellow = needs attention, red = late

- Order prioritization: Automatically sequence by promised time

- Performance tracking: Monitor which stations consistently fall behind

- Real-time alerts: Notify managers when tickets exceed time thresholds

Critical step: Train staff to acknowledge each order immediately upon screen appearance to prevent missed tickets.

Daily Opening and Closing Framework That Ensures Consistency

Implement time-stamped checklists for both opening and closing that guarantee operational consistency across all shifts. Restaurants with detailed daily procedures maintain 32% higher consistency ratings from customers. Your framework must specify exact tasks and completion times.

Essential Opening Checklist (6:00-10:00 AM)

- 6:00 AM: Turn on equipment, check temperatures

- 7:00 AM: Receive deliveries, verify quality

- 8:00 AM: Prep stations set up with par levels

- 9:00 AM: Staff briefing, review specials

- 9:30 AM: Final walkthrough, system checks

Pro tip: Assign one staff member as “checklist captain” responsible for verifying completion of each task.

Staff Recognition System That Cuts Turnover 40%

Implement low-cost, high-impact rewards that make staff feel valued without breaking your budget. Restaurants with structured recognition programs reduce kitchen staff turnover by 40%. Your system must provide immediate, visible acknowledgment of good performance.

Effective Recognition Tactics

- Weekly MVP: Best performer gets first choice of shifts

- Skill badges: Certifications for mastering new stations

- Family meal upgrades: Top performer chooses team meal

- Public shoutouts: Share positive customer feedback in staff meetings

Critical step: Tie recognition to specific behaviors (“Great job handling that rush calmly”) rather than vague praise.

Your immediate action plan: Start with just one system—implement the prep list system this week. Make it specific, measurable, and station-focused. Once your team adapts (typically 2-3 weeks), add the work station checklists. Within 90 days of systematic implementation, you’ll transform from reactive firefighting to proactive management, watching your food costs drop 5-8% and team morale soar. The key to learning how to manage a restaurant kitchen isn’t working harder—it’s implementing these proven systems that work while you sleep.