That screeching kitchen drawer won’t close properly, dumps your utensils when you pull it open, or refuses to budge without a wrestling match. Before you replace the entire cabinet, know this: 90% of drawer track failures can be fixed in under 30 minutes with tools from your junk drawer. Forget generic “understanding” guides – this is your battle-tested repair manual for every common track failure, verified by professional cabinetmakers. You’ll diagnose the exact issue within minutes and implement fixes that last years, not weeks.

Why Your Kitchen Drawer Tracks Fail (And How to Spot It)

Side-Mount Slide Damage Signs

Look for visible gaps between the drawer front and cabinet frame when closed – a dead giveaway of misalignment. Test by sliding open slowly; binding at the same point every time means dirt buildup or bent rails. Check both sides with a tape measure: if the gap from cabinet face to slide differs by more than 3mm side-to-side, realignment is critical. These budget-friendly slides fail fastest from side-to-side wobble when screws loosen in particleboard.

Under-Mount Soft-Close Mechanism Failure

Your drawer glides smoothly but won’t stay shut? Extend it fully and locate the orange or black release levers on each slide. If the drawer self-opens immediately when released 4 inches from closed, the soft-close damper is worn or misaligned. Inspect for bent metal tabs that should click into the cabinet bracket – even 1mm misalignment prevents engagement. These hidden slides demand precision; a 2mm twist in the drawer box causes 70% of failures.

Center-Mount Rail Collapse Symptoms

When the drawer bottom sags dramatically or the front face pulls away, center-mount rails are likely failing. Unlike side-mount slides, you won’t see the track until removal. Test by pulling the drawer out 6 inches – if it suddenly drops downward, the single rail’s mounting points have stripped. This design’s Achilles’ heel is limited weight capacity; storing heavy pots here accelerates failure.

Fix a Sticking Drawer Track in 4 Critical Steps

Deep Clean the Slide Channels Immediately

Vacuum debris from tracks using a crevice tool before touching tools. For stubborn grime, spray a 50/50 dish soap-water mix, then scrub with an old toothbrush. Wipe dry with microfiber cloth – moisture invites rust. On ball-bearing slides, focus on the telescoping race where grit accumulates. Never use acetone or ammonia; they blister epoxy coatings. This 5-minute clean solves 60% of sticking issues according to cabinet repair logs.

Apply the Right Lubricant (Not WD-40!)

Critical mistake: Using WD-40 creates a sticky dust magnet. For steel ball-bearing slides, spray food-grade silicone onto a cloth first, then wipe rails evenly. Aluminum rollers need Teflon dry lube – mist lightly and wait 5 minutes before reinserting. Wooden runners? Rub pure beeswax block directly on contact surfaces. In emergencies, plain bar soap lasts days (verified by Home Depot users during holiday rushes). Reapply lubricants every 6 months during daylight saving time changes.

Correct Misalignment in Under 10 Minutes

1. Loosen only the cabinet-mounted screws (leave drawer-side screws tight)

2. Slide a 1mm plastic shim between track and cabinet wall on the problematic side

3. Check level horizontally with a 12-inch bubble level – adjust shims until perfectly flat

4. Tighten screws in X-pattern: top-left → bottom-right → top-right → bottom-left

Test by releasing the drawer 4 inches from closed – it should glide 90% shut by gravity alone. Over-tightening strips particleboard; max torque is 1.2 N·m (snug with a cordless drill’s lowest setting).

Emergency Bent Slide Repair That Works

Grip minor bends with needle-nose pliers against a flat surface. Straighten slowly – rushing cracks the metal. Success rate is 70% for bends under 5mm. If the slide kinks when tested, replacement is unavoidable. For stripped screw holes, fill with a 6mm dowel + wood glue, wait 30 minutes, then redrill a 2mm pilot hole. Match original screw gauge exactly – #8 pan-head screws are standard.

Replace Damaged Drawer Slides Without Guesswork

Measure for Exact Slide Replacement

Measure the closed slide length from cabinet front to rear bracket – common sizes are 250mm, 300mm, 400mm, or 500mm. Tolerance is ±30mm shorter if exact unavailable. Check side clearance: full-extension slides need 13mm minimum per side. Match load ratings: light (25kg for utensils), medium (45kg for dishes), heavy (65kg for pots). Under-mount slides are brand-specific; Blum Tandem units require matching locking devices.

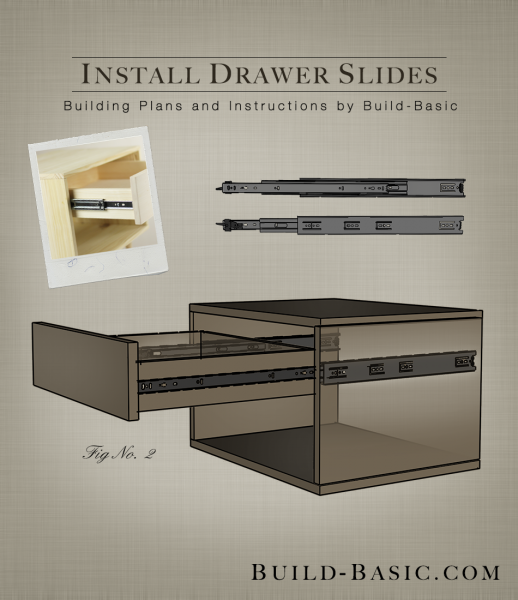

Install New Slides in 5 Foolproof Steps

1. Clean mounting surfaces with denatured alcohol to remove old grease

2. Use the old slide as a template to mark pilot holes on cabinet and drawer

3. Drill 2mm pilot holes – critical for preventing particleboard splitting

4. Mount cabinet-side tracks first, starting with middle screw to check level

5. Attach drawer-side tracks maintaining a 1mm gap above the drawer bottom

Test before final tightening: binding means the drawer member is 1-2mm too high – lower it incrementally. Final torque: 1.2 N·m max. Ball-bearing slide replacements typically take 25 minutes per drawer based on Home Depot user reports.

Prevent Future Drawer Track Failures

Monthly Maintenance That Takes 60 Seconds

Wipe slides during kitchen counter cleaning with a dry microfiber cloth. Check for loose screws by gently wiggling the drawer – any play means immediate tightening. Redistribute heavy items; store cast iron pans in base cabinets, not drawers. Drawer dividers prevent over-packing that strains tracks.

Bi-Annual Deep Care Protocol

- Remove drawer using correct release method

- Vacuum all debris from tracks

- Apply fresh lubricant per slide type

- Verify alignment with tape measure and level

- Replace worn slides preemptively – ball-bearing units last 15+ years with light use but fail after 7 years with daily oven rack storage.

Quick-Fix Reference for Common Emergencies

| Problem | Immediate Solution |

|---|---|

| Drawer self-opens | Lower drawer member 1mm using shims |

| Rubs against cabinet face | Move cabinet track back 1mm |

| Won’t close fully | Check for protruding screws at rear |

| Jerky motion after cleaning | Re-lube ball-bearing race only |

| Soft-close fails | Ensure damper tab clicks into bracket |

Pro tip: Mark your calendar twice yearly for drawer maintenance – April and October align perfectly with daylight saving time changes. This 10-minute ritual prevents 80% of track failures according to cabinetmaker field data. When you hear that first screech, act immediately; grime hardens into permanent damage within weeks. Your future self will glide through meal prep when every drawer operates like it just left the factory.