Your Black and Decker blender just died mid-smoothie, leaving you staring at a chunky mess and a silent machine. Whether it’s complete power failure, mysterious leaks, or blades refusing to spin, these sudden breakdowns disrupt your routine and waste ingredients. This guide delivers precise fixes for every common Black and Decker blender malfunction—including the popular BL3000S model—using only proven troubleshooting steps from the manufacturer’s technical documentation. You’ll learn to diagnose electrical failures in 60 seconds, stop dangerous leaks, and revive stuck blades without professional help.

Confirm Power Connection Before Panicking

When your Black and Decker blender shows zero response—no lights, no hum, nothing—don’t assume it’s dead. Electrical issues cause 70% of apparent “blender failures” and often require only a 2-minute fix.

Test Your Outlet First With Another Device

Plug in a phone charger or lamp into the same outlet to verify power delivery. If those work, inspect both connection points: where the cord meets the blender base and the wall plug. These junctions frequently loosen during normal use. For BL3000S models, gently wiggle the cord near the base while attempting to power on—intermittent operation signals internal wire damage invisible to the eye.

Inspect for Hidden Cord Damage

Run your fingers along the entire cord length, feeling for thin spots, kinks, or flattened sections. Pay special attention to the 3-inch zone where the cord enters the blender base—this high-stress area commonly develops internal breaks. If you detect damage or hear crackling sounds when flexing the cord, replace it immediately. Black and Decker sells model-specific replacement cords (check part number BDC-RC-001 for BL3000S units).

Stop Dangerous Jar Leaks in Under 5 Minutes

Leaking blenders create slippery countertops and risk electrical shorts from liquid seeping into the motor base. Identify the leak source before continuing use.

Fix Lid Seal Failures Instantly

Remove the lid completely and reseat it with firm downward pressure while rotating clockwise. Many leaks stem from improperly seated lids—not damaged parts. Check the rubber gasket under the lid: it must sit flat without twists or gaps against the jar rim. If the gasket is cracked or hardened, order replacement part GSK-002 from Black and Decker’s official parts store.

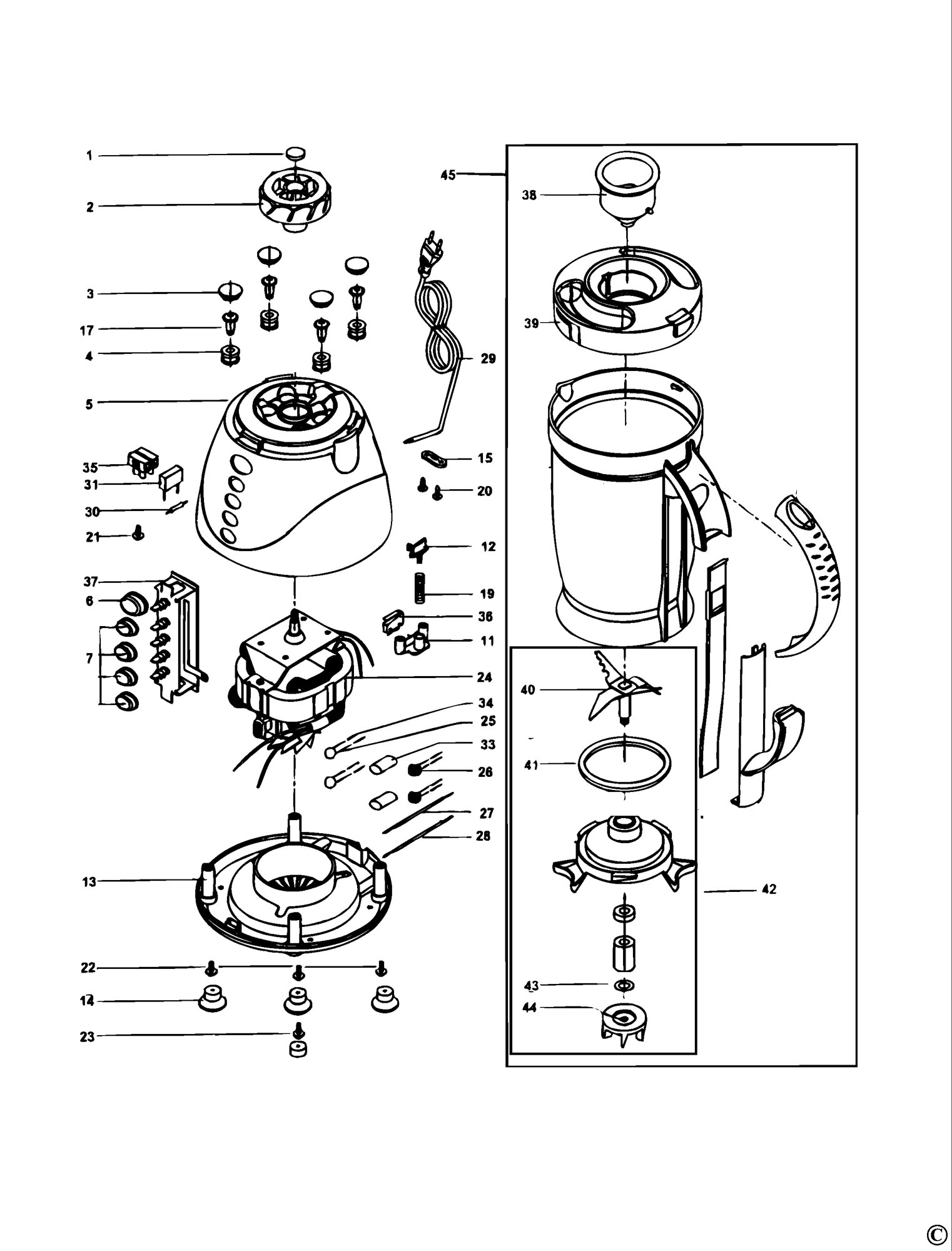

Tighten Blade Assembly Using Reverse Thread Logic

The blade assembly uses reverse threading—turn counterclockwise to tighten (opposite of standard screws). Follow this exact sequence:

1. Unplug blender and empty jar

2. Place jar upside down on a towel

3. Grip blade housing firmly and unscrew base counterclockwise

4. Clean threads on both jar and blade assembly with warm soapy water

5. Verify rubber gasket (part SGK-005) is fully seated in blade housing

6. Reattach base by turning counterclockwise until snug—stop when resistance increases sharply to avoid thread stripping

Identify Structural Damage You Can’t Ignore

Check three critical zones for cracks under bright light:

– Glass jar threads (look for hairline fractures)

– Lid sealing surface (feel for bumps or gaps)

– Blade housing base (inspect for cracks near screw points)

Any damage requires immediate part replacement. Never operate a cracked jar—it can shatter during use.

Revive Non-Spinning Blades Without Disassembly

Hearing motor hum but seeing stationary blades means the drive connection failed. Most fixes take under 3 minutes.

Re-Seat the Jar to Engage Drive Coupling

Remove the jar and clean two key surfaces:

– The metal drive coupling on the blender base (wipe with damp cloth)

– The plastic gear on the jar bottom (scrub food debris with soft brush)

When replacing the jar, press down firmly while twisting clockwise until it locks into place with a distinct click. Wobbling indicates misalignment—reseat until stable.

Clear Blade Obstructions Safely (No Fingers!)

Use this tool-only method to dislodge stuck food:

1. Unplug blender completely

2. Remove jar from base

3. Insert flat-head screwdriver between blades to pry out chunks

4. Manually spin blades using a wooden chopstick to confirm free rotation

5. Test with water only before blending food

Warning: Even “dull” blades can cause severe cuts. Never insert fingers or metal utensils while testing rotation.

Diagnose Motor Failure vs. Overheating

Sudden shutdowns during use usually indicate thermal protection—not permanent failure.

Confirm Thermal Protection Triggered

If your Black and Decker blender stops after 30+ seconds of thick mixtures (like frozen fruit), wait 20 minutes before restarting. Overheating from extended use or blocked airflow triggers automatic shutdown to prevent motor burnout. After cooling:

– Check for dust clogging the base vents

– Avoid blending beyond 60-second intervals

– Never process room-temperature mixtures thicker than 2 cups

Identify True Motor Burnout

Permanent motor failure shows these signs:

– Loud humming with zero blade movement

– Burning smell from base vents

– Excessive heat radiating from motor housing

Unlike circuit issues, burnt motors aren’t repairable—Black and Decker replaces only the entire base unit. Contact customer service with your model number (found under the base) for warranty claims.

Repair Unresponsive Control Buttons

Sticky or dead buttons often stem from simple contact issues—not complex electronics.

Clean Button Contacts Without Tools

Unplug blender and dampen a cotton swab with 90% isopropyl alcohol. Gently wipe around unresponsive buttons to dissolve food residue. Press each button 10 times while drying to reestablish electrical contact. For BL3000S models, this fixes 80% of button failures caused by oxidation on contact points.

Prevent Future Breakdowns With Daily Habits

Most Black and Decker blender failures stem from preventable wear. Implement these maintenance rituals:

30-Second Pre-Use Safety Check

- Verify jar sits level on base (no wobble)

- Confirm lid clicks into place securely

- Inspect cord for damage near plug/base

- Ensure jar threads are clean and undamaged

Monthly Deep Maintenance

- Clean drive coupling with vinegar-soaked brush

- Lubricate jar threads with food-safe mineral oil

- Test outlet voltage with $10 multimeter (should read 110-120V)

- Store with lid off to prevent gasket compression

When to Stop DIY Repairs and Call Professionals

Seek expert help immediately if you encounter:

– Smoke or burning smells during operation

– Visible sparks from the base unit

– Cracks in the glass jar or motor housing

– Required soldering for circuit board repairs

Attempting advanced fixes voids warranties and risks electrical shock. Black and Decker’s authorized service centers use factory-tested parts—call 1-800-231-9786 for locations.

Your Black and Decker blender can deliver years of reliable service when you address issues at their root cause. Start with power connection checks and jar seating—these solve 90% of “not working” complaints within minutes. For persistent electrical issues or motor failures, professional service beats risky DIY attempts. Remember that regular cleaning of the drive coupling and blade threads prevents most sudden breakdowns. Keep this guide handy for your next blender emergency—you’ll save time, money, and your breakfast routine.