Ever wonder what happens inside your kitchen faucet when you turn the handle? That simple motion triggers a sophisticated engineering process delivering perfectly mixed water for everything from washing dishes to filling pasta pots. Understanding how a kitchen faucet works isn’t just interesting—it’s practical knowledge that helps you troubleshoot problems, extend your faucet’s lifespan, and make smarter replacement decisions when the time comes.

Most homeowners interact with their kitchen faucet dozens of times daily without considering the precision mechanics hidden beneath the sink. Whether you’re dealing with a persistent drip, inconsistent water temperature, or simply planning your next kitchen upgrade, knowing the inner workings transforms you from a passive user to an informed homeowner who can address issues before they become expensive repairs.

Single-Handle Mechanics: Precise Control in One Motion

Your single-handle faucet delivers both flow and temperature control through a single lever’s movement. Lift the handle upward to increase water volume, then rotate left for hotter water or right for cooler temperatures. This dual-action design creates a seamless experience where handle position directly corresponds to water output.

Inside this elegant system, your handle connects to a cartridge that simultaneously controls both hot and cold water valves. When you lift the handle higher, both valves open wider to increase total flow. The rotation angle determines how much each valve opens—more hot water when turned left, more cold when turned right. This precise mechanical coordination happens in milliseconds, giving you instant control over your water.

Why Single-Handle Faucets Leak at the Base

If water seeps from around your faucet handle when in use, worn cartridge seals are almost always to blame. These rubber or plastic O-rings create watertight barriers between moving parts. Over time, mineral deposits and normal wear cause them to lose elasticity. Replacing these inexpensive seals—typically requiring just a screwdriver and replacement kit—solves 90% of base leaks without professional help.

Double-Handle Systems: Traditional Control with Precision

Double-handle faucets offer separate control for hot and cold water through two independent valves. Each handle connects directly to its own valve stem, allowing you to fine-tune temperature by adjusting the ratio of hot to cold water. While requiring two hands for temperature changes, this design provides exceptional precision for tasks requiring exact water temperatures.

Unlike single-handle systems where one cartridge controls both temperatures, double-handle faucets isolate each valve mechanism. This means a problem with your hot water handle won’t affect cold water operation, making troubleshooting simpler. When one handle develops issues, you can often repair just that side without disturbing the entire system.

When to Choose Double-Handle Over Single-Handle

Double-handle faucets excel in situations requiring precise temperature control, such as commercial kitchens or homes with older plumbing systems prone to pressure fluctuations. They’re also ideal for vintage or traditional kitchen designs where matching period aesthetics matters. If you frequently experience sudden temperature changes when someone flushes a toilet elsewhere in the house, the independent control of double-handle systems provides more stable water temperatures.

Ceramic Disc Valves: The Modern Standard for Reliability

Ceramic disc valves represent the gold standard in modern faucet technology. Inside these systems, two precisely engineered ceramic discs—one stationary, one moving with your handle—slide against each other to control water flow. Matching holes in both discs align to create water pathways, with their relative positioning determining the hot/cold water ratio.

These diamond-hard ceramic components resist corrosion and mineral buildup that plague older designs. Unlike rubber washers that degrade over time, ceramic discs maintain their integrity for decades under normal conditions. This durability translates to maintenance-free operation for 10-15 years in most homes, with cartridge replacement taking less than 15 minutes when eventually needed.

How to Identify a Failing Ceramic Disc Cartridge

When your ceramic disc faucet starts dripping from the spout, the cartridge needs replacement. Unlike compression faucets that leak only when handles are partially open, ceramic disc systems typically develop persistent drips regardless of handle position. You’ll notice water continuing to flow for several seconds after turning off the faucet—a clear sign that the ceramic discs no longer form a perfect seal. Replacement cartridges cost $15-$40 and require only basic tools.

Ball Valve Systems: The Workhorse of Older Designs

Ball valve faucets, popularized by Delta in the 1970s, use a single rotating ball mechanism with precisely engineered chambers and slots. As you rotate the handle, the ball turns to align different ports with the hot and cold water inlets, controlling both flow and temperature through this single moving part.

While less common in new installations today, millions of ball valve faucets remain in service. These systems require more frequent maintenance than ceramic disc designs due to multiple rubber seals and springs inside the ball assembly. Replacement kits with color-coded parts make repairs straightforward, though you’ll need to replace these components every 3-5 years depending on water quality.

Why Ball Faucets Lose Temperature Control

If your ball valve faucet delivers inconsistent temperatures—sometimes scalding hot, other times unexpectedly cold—the ball assembly seals have likely worn out. These rubber components lose elasticity over time, allowing water to bypass the intended flow paths. The solution involves replacing the entire ball valve repair kit, which includes all internal seals and springs. This $10-$20 repair restores precise temperature control and prevents annoying drips.

Water’s Journey: From Pipes to Your Sink

Understanding water’s path through your faucet helps diagnose flow problems and appreciate the engineering hidden beneath your sink. Water enters through two braided supply lines connected to your home’s plumbing—one for hot water from your water heater, one for cold directly from the main supply.

Mixing Chamber Mechanics

Inside the faucet body, hot and cold water streams meet in the mixing chamber where the valve system controls their ratio. In ceramic disc faucets, the alignment of holes in the rotating and stationary discs determines how much of each water source combines. Advanced systems include pressure-balancing features that automatically adjust when someone flushes a toilet or starts a washing machine, maintaining consistent water temperature despite pressure fluctuations elsewhere in your plumbing.

Spout Delivery Dynamics

After mixing, water travels upward through the spout assembly to the aerator or spray head. Fixed spouts deliver water in a single direction, while pull-out and pull-down designs route water through flexible hoses. The aerator at the spout tip adds air to the stream, reducing splash while maintaining effective flow rate. When you notice weak flow, clogged aerator screens—easily cleaned with vinegar—are the culprit 80% of the time.

Spout Types: Matching Design to Functionality

Your spout choice dramatically impacts daily kitchen functionality. Each design serves specific needs, from filling tall stockpots to rinsing every corner of your sink.

Fixed Spout Advantages and Limitations

Straight spouts provide maximum horizontal reach with minimal vertical clearance—ideal for standard sinks where overhead space is limited. Gooseneck designs offer generous clearance for filling large containers but may create splashback in shallow sinks. Shepherd’s crook spouts combine visual appeal with functional reach, making them popular in traditional and farmhouse-style kitchens.

Dynamic Spout Systems for Maximum Flexibility

Pull-out spouts feature retractable spray heads on lengthy hoses, perfect for targeted cleaning and filling containers on adjacent countertops. Pull-down spouts use shorter, weight-balanced hoses that extend downward into deep sinks, with magnetic docking ensuring smooth retraction. If you frequently wash large pots or need to clean hard-to-reach sink corners, these dynamic systems significantly enhance kitchen functionality.

Mounting Systems: Ensuring Long-Term Stability

Your faucet’s mounting system determines both installation complexity and long-term stability. Most residential kitchens use deck-mounted systems secured through pre-drilled holes in your sink or countertop.

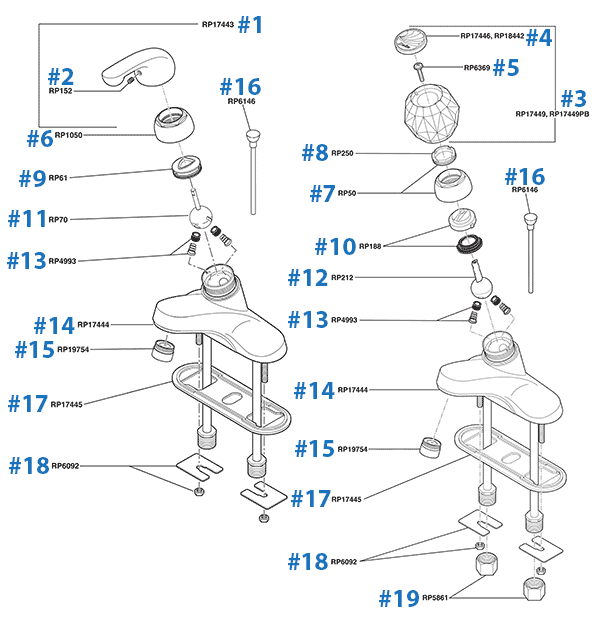

Deck Mount Components Explained

The base plate (escutcheon) serves dual purposes—covering unused mounting holes while providing a stable platform. Threaded mounting hardware secures the faucet body, while rubber gaskets create watertight seals preventing moisture infiltration that causes cabinet damage. When your faucet becomes loose over time, tightening the mounting nuts underneath the sink usually solves the problem.

Hole Configuration Compatibility

Standard sinks accommodate 1-hole (single-handle), 3-hole (widespread), or 4-hole (widespread plus sprayer) configurations. Many modern faucets include optional escutcheon plates to adapt single-hole designs for multi-hole sinks, providing flexibility during replacement projects. Before purchasing a new faucet, measure your sink’s hole configuration to ensure compatibility.

Flow Rate Standards: Balancing Performance and Conservation

Modern faucets balance performance with water conservation through carefully regulated flow rates. Understanding these standards helps you choose replacement parts or evaluate new faucet purchases.

WaterSense Certification Benefits

WaterSense certified models cap flow at 1.5 gallons per minute (GPM), reducing consumption by 20% compared to standard faucets (1.8-2.2 GPM) while maintaining adequate pressure. These models feature advanced aerator technology that adds more air to the stream, creating the sensation of higher flow without using extra water. When replacing an aerator, matching the original flow rate ensures consistent performance.

Maintenance Essentials: Preventing Costly Repairs

Regular maintenance extends faucet life from the standard 10-15 years to potentially decades of reliable service. Understanding common failure points helps you address issues before they become expensive problems.

Annual Maintenance Checklist

- Clean aerator screens quarterly to prevent mineral buildup

- Check supply line connections for corrosion or moisture

- Test handle operation for smooth movement

- Inspect visible components for leaks or drips

Hard water accelerates mineral buildup in valves and aerators, requiring more frequent cleaning. Soaking affected parts in white vinegar for 30 minutes dissolves most mineral deposits without damaging components. For severe buildup, consider installing a point-of-use water filter to extend component life.

Your kitchen faucet represents sophisticated engineering hiding in plain sight. By understanding how a kitchen faucet works—from ceramic disc precision to dynamic spout flexibility—you gain the knowledge to maintain it properly, troubleshoot common issues, and make informed decisions when replacement becomes necessary. Whether you’re tightening a loose handle or planning a complete upgrade, this insight ensures you’ll appreciate the complex choreography happening every time you turn on the tap, transforming a simple household fixture into a reliable tool for daily kitchen tasks.